What are the types of environmentally friendly dust removal equipment for lime kilns

During the lime production process, lime kilns emit a large amount of dusty exhaust gas, causing serious pollution to the environment. In order to achieve clean production, various types of environmental dust removal equipment have emerged, playing a key role in the environmental management of lime kilns.

Mechanical dust removal equipment

Dust chamber: This is a dust removal equipment that uses gravity to settle dust. When the dusty gas enters the dust chamber, due to the decrease in airflow velocity, heavier dust particles gradually settle to the bottom of the chamber under the action of gravity, thereby achieving gas-solid separation. Its structure is simple, the operating cost is low, but the dust removal efficiency is relatively low, and it is generally suitable for processing larger particle sizes of dust.

Cyclone dust collector: This equipment utilizes the inertial force caused by the swirling motion of the airflow to separate and settle the dust. After entering the cyclone dust collector at a high speed along the tangential direction, the dusty gas rotates inside the cylinder. The dust is thrown towards the wall of the collector by centrifugal force and falls down along the wall to the ash hopper. The purified gas is discharged from the top. Cyclone dust collectors have the advantages of simple structure, small footprint, and easy maintenance. The dust removal efficiency is generally between 50% and 90%, and they are commonly used for pre dust removal or in combination with other dust removal equipment.

Inertial dust collector: It uses the inertial force caused by the flow of air in the equipment to achieve the separation and settling of dust. When the dusty gas passes through the inertial dust collector, the direction of the airflow changes sharply, and the dust separates from the airflow due to inertia and settles at the bottom of the equipment. Inertial dust collectors are suitable for processing dust with larger particle size and higher density, but have poor dust removal effect on fine dust.

Filter type dust removal equipment

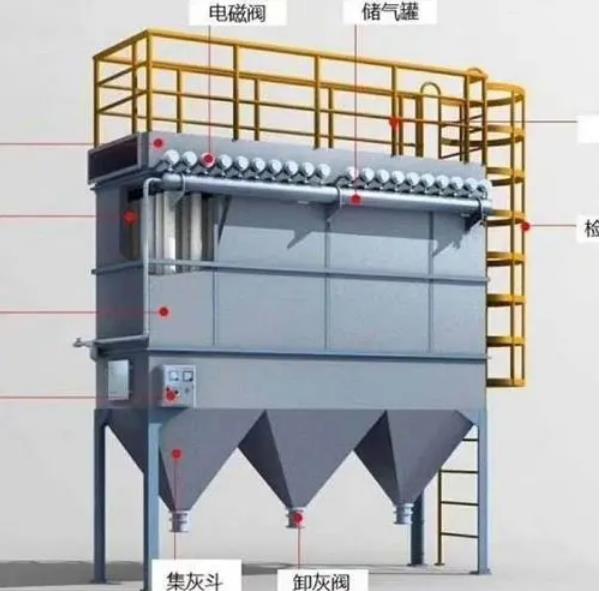

Bag type dust collector: A bag type dust collector is a dry dust filtering device that purifies the airflow through a filtering method. After the dusty gas enters the bag filter, the dust is trapped on the surface of the filter bag, and the purified gas is discharged through the filter bag. As dust accumulates on the surface of the filter bag, the resistance and efficiency of the dust collector will change. When the resistance reaches a certain value, dust cleaning operation is required. Bag filter has the advantages of high dust removal efficiency, strong adaptability, and stable operation. The dust removal efficiency can reach over 99%, and it is widely used in the dust removal treatment of lime kilns. For example, a lime kiln bag filter consists of an inlet, pretreatment equipment, bag filter chamber, outlet, and ash cleaning system. The inlet introduces exhaust gas and dust, the pretreatment equipment removes large particle impurities, the bag filter chamber filters, and the purified exhaust gas is discharged from the outlet. The material of its filter bag can be selected according to the properties of the material, with a wide range of applications and a reasonable cleaning procedure and cleaning cycle, ensuring the cleaning effect of the dust collector and the service life of the filter bag.

Water dust collector: The water dust collector uses the sprayed water flow to wet and settle the dust. After the dusty gas comes into contact with water, the dust is wetted by the water and settles to the bottom of the equipment along with the water flow. Water dust collectors have the advantages of simple structure, low investment, and low operating costs, but they generate sewage and require sewage treatment, and have poor treatment effects on high temperature and high humidity gases.

Electric dust removal equipment

Electric dust collector: An electric dust collector separates dust by moving it towards electrodes with opposite charges. In an electrostatic precipitator, the dust containing gas is ionized and charged by a high-voltage electric field, and then moves towards the electrode under the action of the electric field force, depositing on the electrode. Finally, the dust is removed from the electrode by vibration or other methods. Electric dust collectors have the advantages of high dust removal efficiency, large gas processing capacity, and low resistance. However, they require high equipment investment and operating costs, and have certain requirements for the electrical resistivity of dust. They are suitable for processing high concentration and fine dust gases.

Combination dust removal equipment

In practical applications, in order to achieve better dust removal effects, multiple dust removal equipment are often combined and used. For example, combining a cyclone dust collector with a bag filter, the cyclone dust collector serves as a pre dust removal device to remove most of the coarse dust, reduce the burden on the bag filter, and improve the service life and dust removal efficiency of the bag filter. For example, combining a water dust collector with an electric dust collector, first using the water dust collector to remove some dust and harmful gases, reducing gas temperature and humidity, and then using the electric dust collector for deep purification.

Lime kiln dedicated environmental protection dust removal equipment

Cyclone water film dust removal tower: This is one of the commonly used environmentally friendly dust removal equipment in lime kilns. It combines the principles of cyclone dust removal and water film dust removal. After the dust containing gas enters the dust removal tower, it undergoes preliminary separation in the cyclone section and then enters the water film section. The dust is captured by the water film and discharged with the water flow. The cyclone water film dust removal tower has the advantages of high dust removal efficiency, small footprint, and stable operation, which can effectively remove dust and some harmful gases from lime kiln exhaust gas.

Turbulent ball desulfurization tower: Turbulent ball desulfurization tower is mainly used for desulfurization and dust removal in lime kilns. Lightweight hollow spheres are installed inside the tower as packing materials. When dust and sulfur-containing gases pass through the packing layer, they come into full contact with the sprayed absorbent and undergo chemical reactions, thereby achieving the purpose of desulfurization and dust removal. The turbulent ball desulfurization tower has the advantages of high desulfurization efficiency, low resistance, and high operational flexibility, which can effectively reduce the emission of sulfur dioxide in lime kiln exhaust gas.

There are various types of environmental dust removal equipment for lime kilns, each with its own characteristics and applicable scope. In practical applications, appropriate dust removal equipment or combination methods should be selected based on factors such as the production scale, exhaust gas characteristics, and emission standards of the lime kiln, in order to achieve clean production and environmentally compliant emissions of the lime kiln.