One stop supply of complete equipment for lime shaft kiln

For lime producers seeking a seamless, cost-effective path to establishing or upgrading their shaft kiln operations, complete equipment integration from a single supplier is the cornerstone of success. Linyi Jinyong Kiln Co., Ltd., a pioneer in China’s lime industry, specializes in delivering turnkey solutions for lime shaft kiln projects, covering design, manufacturing, installation, and technical support.

Comprehensive Equipment Suite for Optimal Performance

Jinyong Kiln’s one-stop supply model eliminates the complexities of sourcing from multiple vendors by offering a fully synchronized equipment lineup:

Vertical Shaft Kiln Core Units

Kiln Body Structure: High-strength steel shells paired with modular refractory linings, engineered for 10+ years of service life.

Precision Combustion Systems: Adjustable burners with real-time oxygen-flue gas ratio control, ensuring uniform calcination (CaO ≥90% stability).

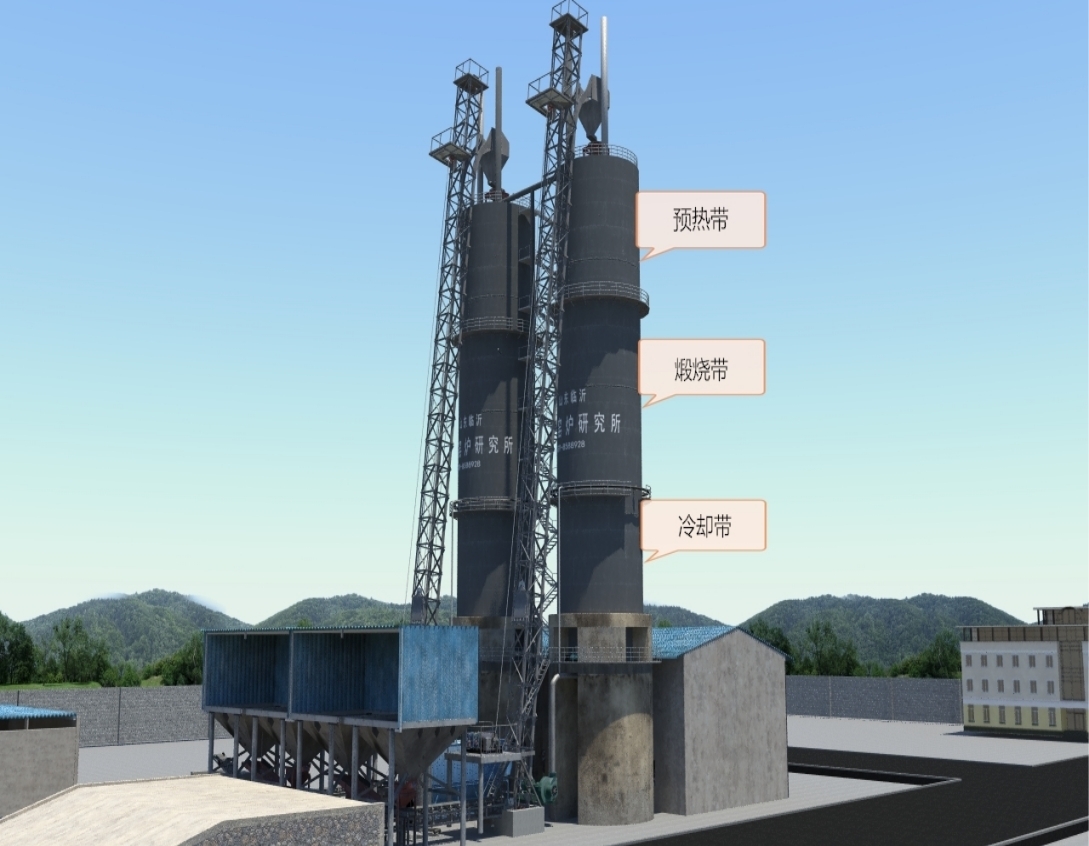

Advanced Airflow Management: Dual-channel air distribution technology to balance preheating, calcination, and cooling zones, reducing energy waste by 18–22%.

Auxiliary Equipment Synergy

Intelligent Crushing & Screening: Jaw crushers and vibrating screens with adjustable particle size control (0–50mm) for raw material uniformity.

Automated Feeding & Discharge: Belt conveyors, bucket elevators, and hydraulic unloaders for 24/7 continuous operation with minimal labor.

Emission-Control Systems: Pulse-jet bag filters and desulfurization towers meeting China’s ultra-low emission standards (SO₂ <35mg/m³, dust <10mg/m³).

Technical Advantages Driving Profitability

Energy Efficiency: Jinyong’s shaft kilns consume 115–125 kg coal/ton of lime, 10–15% lower than industry averages.

Digital Control: SCADA-based monitoring systems enable remote parameter adjustment, reducing over-burning/under-burning risks.

Modular Scalability: Kiln capacities range from 100 to 600 tons/day, with expandable designs to align with future production growth.

Global-Ready Service & Compliance

Certified Quality: ISO 9001, CE, and environmental management certifications ensure compliance with domestic and international standards.

End-to-End Support: From site layout planning to operator training, Jinyong’s 50+ engineers provide on-site commissioning and 2-year warranty coverage.

Export-Optimized Logistics: Anti-corrosion packaging and custom clearance assistance for seamless delivery to Southeast Asia, the Middle East, and Africa.

Why Choose Jinyong Kiln?

By consolidating complete equipment for lime shaft kiln under one roof, Jinyong Kiln eliminates compatibility risks, shortens project timelines, and reduces long-term maintenance costs. Clients in steel, chemical, and construction industries have achieved ROI within 18–24 months through enhanced productivity and lower operational expenses.

For lime producers aiming to lead in an era of stricter regulations and market competition, Jinyong Kiln’s one-stop supply model is the key to unlocking sustainable, high-margin production.

Contact Jinyong Kiln today to discuss your project requirements and receive a tailored equipment proposal.