What are the technical advantages of vertical environmental protection lime kiln

As an innovative equipment in the field of lime production, the vertical environmentally friendly lime kiln has become the core carrier of the industry's green transformation with its multidimensional technological advantages. Its core advantages are reflected in four aspects: energy conservation and consumption reduction, environmental compliance, intelligent control, and resource recycling.

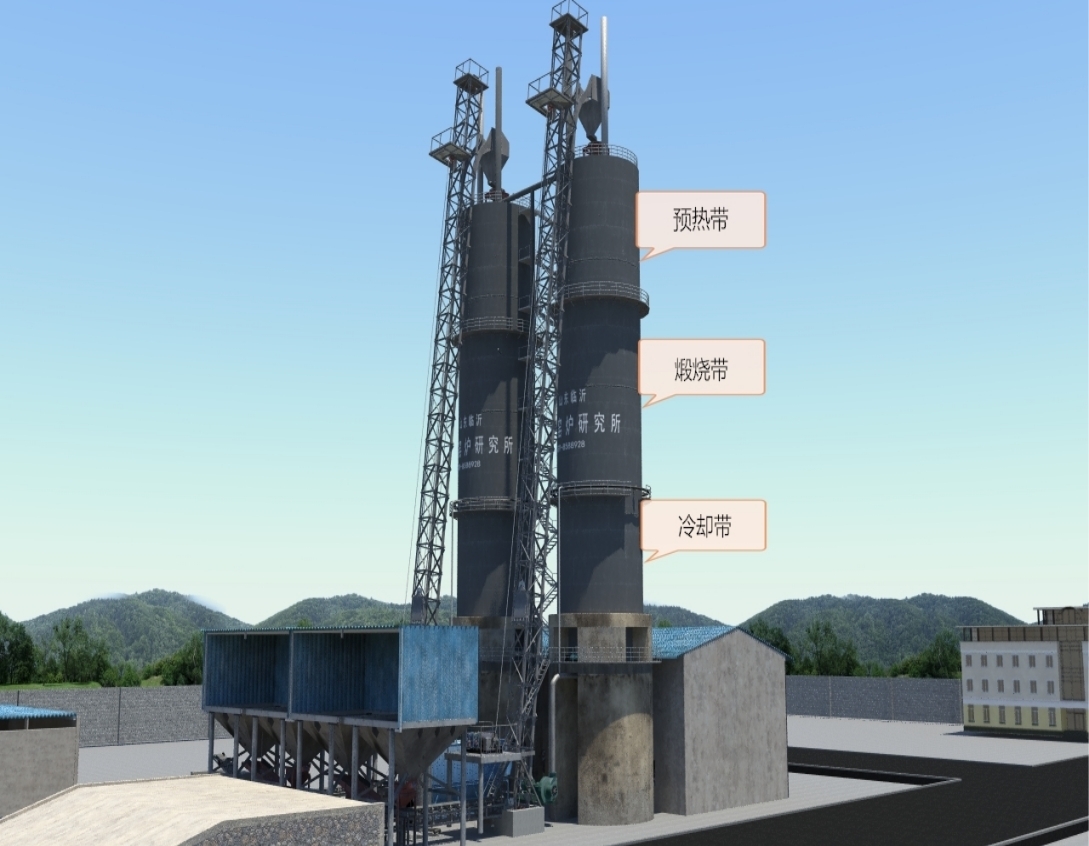

Efficient and energy-saving technology is the core competitiveness of vertical environmentally friendly lime kilns. Through a fully enclosed negative pressure calcination design, combined with a variable frequency control system, precise speed regulation of key equipment such as Roots blowers and winches is achieved, resulting in an energy savings rate of over 40%. The furnace body adopts a composite insulation structure, with a gradient insulation layer formed by the inner layer of high alumina bricks and the outer layer of aluminum silicate fiber felt, effectively reducing heat loss. Taking the EEAS type vertical kiln as an example, its standard coal consumption is less than 130kg/t lime, and its thermal efficiency is increased by more than 25% compared to traditional kilns.

In terms of environmental compliance, the kiln is equipped with a multi-stage purification system consisting of a pulse bag filter and a turbulent ball desulfurization tower. The particle emission concentration is stably controlled at 30-40mg/m ³, far below the national emission standard of 50mg/m ³. For tar containing waste gas, an innovative smoke dust mixing dust removal process is adopted, which increases the diameter of tar particles through CaO dust adsorption, solves the problem of filter bag blockage, and achieves ultra-low emissions.

The deep integration of intelligent control systems significantly improves production stability. The PLC control platform collects real-time parameters such as temperature, pressure, and air volume, combined with the variable frequency speed regulation function of the rotating fabric feeder, to ensure uniform distribution of materials. The equipment produced by Zhengzhou Mining Machinery in Henan Province has achieved single kiln and single person operation. The fault warning system can predict equipment abnormalities 12 hours in advance and compress unplanned downtime to less than 2 hours.

The construction of a resource recycling system highlights the concept of sustainable development. The waste heat recovery device at the kiln tail converts 1200 ℃ high-temperature flue gas into steam or electricity, meeting 30% of the electricity demand in the factory area. After crushing and screening, 85% of the kiln slag can replace sand and gravel for road base paving, with an annual solid waste treatment capacity of 20000 tons. Taking a 250m ³ kiln as an example, its CO ₂ capture device can produce 10 tons of industrial grade carbon dioxide per hour, achieving carbon resource utilization.

The synergistic effect of these technological advantages enables vertical environmentally friendly lime kilns to save 30% energy and reduce emissions by 45% compared to traditional equipment, while maintaining product activity above 300ml and a raw firing rate of less than 5%. The application practice in Wu'an, Hebei and Liuzhou, Guangxi has shown that the investment payback period of this kiln type is only 5-6 months, making it a key equipment for promoting the high-quality development of the lime industry.